In the world of Personal Protective Equipment (PPE), innovation is not just a goal—it’s a necessity. At Davlyn Group, we are proud to lead the charge with our CHOICE® line of aluminized fabrics, setting a new standard for quality and performance in the market. As the worldwide leader in aluminized fabrics, we are committed to providing superior protection and durability to sewn product manufacturers of PPE and industrial heat protective products.

Learn why our aluminized fabrics are raising the bar for robust PPE solutions.

What Are Aluminized Fabrics?

Aluminized fabrics are wearable textiles that feature an engineered laminate of aluminized material. Aluminized fabrics have become the benchmark for PPE in close-proximity applications that require protection from radiant heat sources and molten metal splash, such as firefighting and working with molten iron. Common PPE clothing designed with aluminized fabrics include gloves, mitts, coats, and pants. Aluminized fabrics can also be incorporated into radiant heat shields, such as curtains, hose and wiring protection, and other industrial applications.

Davlyn Group’s CHOICE® aluminized fabrics offer unparalleled safety for wearers in hazardous environments by reflecting radiant heat and providing robust resistance against molten metal splashes. Durability in use is a hallmark of the CHOICE® line of aluminized fabrics, providing the user with lifecycle cost advantages of competitive products.

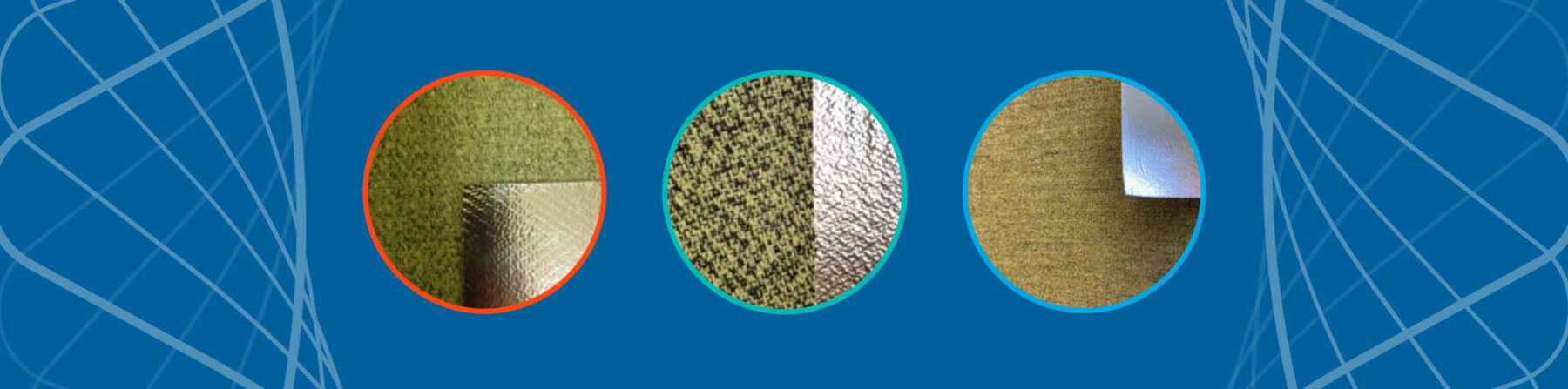

Aluminized Fabrics Up Close

The choice and quality of materials for use in the base layer fabric and in the engineered aluminized surface is critical to the level of protection and durability in challenging end-use environments. Davlyn Group and its predecessor, Norfab Corporation, have been designing, specifying, and selling aluminized fabrics since 1979.

The base layer construction, whether warp knit, woven, or nonwoven fabric, is an essential component of aluminized fabrics that provides insulation and flexibility. Many of the base layer fabrics add significant cut and puncture protective properties to the aluminized composite. The engineered aluminized surface reflects radiant heat and repels the adhesion of molten metals to the fabric surface.

Aluminized fabrics are constantly evolving to achieve the lowest weight while maintaining necessary protection levels. A full range of aluminized fabrics is available to meet stringent industry standards including NFPA 1971, ASTM F955, and ISO 11612.

Davlyn Group’s CHOICE® fabrics are highly flexible and offer a range of weights depending on the end-use application. In addition to the aluminized surface, base fabrics may be composed of a range of flame-retardant fiber types that include para-aramid, meta-aramid. PBI, oxidized PAN (OPF), and fiberglass.

Innovation Is at Our Core

Davlyn Group is not just a supplier; we are an innovator in PPE aluminized fabrics. Our dedication to advancing PPE technology is evident in our continuous introduction of new fibers, new fiber blends, as well as improvements in fabric structure. These enhancements are designed to boost workplace mobility in aluminized garments, ensuring that safety does not come at the expense of comfort or functionality.

One of our key innovations is the CHOICE® solvent-free aluminizing process, which reduces the environmental impact of aluminized fabrics. This formula is a testament to our environmentally friendly manufacturing practices and addresses the PPE industry’s growing emphasis on sustainability. Davlyn Group’s technical adhesive technology also ensures the durability and longevity of our aluminized fabrics, even in the harshest of working conditions.

Why the CHOICE® Is Clear

The CHOICE® line represents the pinnacle of innovation, durability, and customer-centric design in aluminized fabrics.

Rigorous Testing & Proven Performance

The introduction of our CHOICE® line followed 15 months of rigorous field trials and long-term testing, which included standard shelf-life testing and exposure to known chemical contaminants. The results were clear: our CHOICE® products performed best in class in the category, cementing our position as a leader in the market since 2014.

Unmatched Customer Support

In the PPE industry, customer feedback is swift and unfiltered. Davlyn Group responds quickly to any issues that may arise, whether during manufacturing or in the field. This proactive approach allows us to learn, adapt, and continuously improve our products. Customer feedback provides valuable insights into new development opportunities, ensuring that we remain at the forefront of innovation.

Market Demand & Longevity

The demand for aluminized fabrics in PPE remains steady, driven by the need for products with excellent lifecycle costs. Higher quality products, even at a higher cost, are gaining market share due to their demonstrated longer life cycles. At Davlyn Group, we understand this market dynamic and continue to incorporate new flame-resistant fibers and blends into the base fabrics we produce for aluminizing.

Strategic Partnerships

Our commitment to quality and innovation extends beyond our in-house capabilities. We partner with a world-class coating and laminating company that brings significant chemistry and manufacturing resources to the table. This collaboration ensures that our aluminized fabrics meet the highest standards of performance and reliability.

A Dedicated Partner in PPE

As we continue to push the boundaries of PPE technology, we remain focused on providing superior protection for those who need it most.

For more information on our CHOICE® aluminized fabrics and how they can enhance your PPE products, contact us today. Our team of experts is ready to provide the technical assistance and advice you need to make the best choice for your protective equipment needs.